Já pensou em ter uma solução em geração de energia para sua empresa crescer a todo vapor?

Se sua indústria utiliza vapor no processo ou tem resíduos disponíveis, sua empresa tem potencial para geração de energia elétrica e ser autossuficiente, podendo ainda gerar novas receitas vendendo o excedente.

Ou se já possui um conjunto turbogerador em operação e quer ainda mais eficiência, aplique também as soluções WEG.

Quais são os objetivos da sua indústria?

- Eliminar resíduos, reduzir o impacto ambiental e ser sustentável em energia verde?

- Ser autossuficiente e independente da rede pública?

- Vender sua própria energia e gerar novos lucros?

- Reduzir custos e se tornar mais competitiva no mercado?

- Reduzir custos operacionais com altas tarifas de energia elétrica?

Seja qual for a sua resposta, para todas essas perguntas, a WEG tem as soluções.

Sabe o porquê de a WEG ser a melhor escolha para a sua indústria?

Porque a WEG é referência no desenvolvimento de projetos que transformam energia em soluções. Com ampla capacidade produtiva e expertise tecnológica, todos os equipamentos são fabricados e implantados para atender clientes dos mais diversos portes e segmentos, garantindo alta performance e máxima eficiência nos processos produtivos.

Confie na agilidade e na capacidade de quem vai mais longe para estar sempre perto de você.

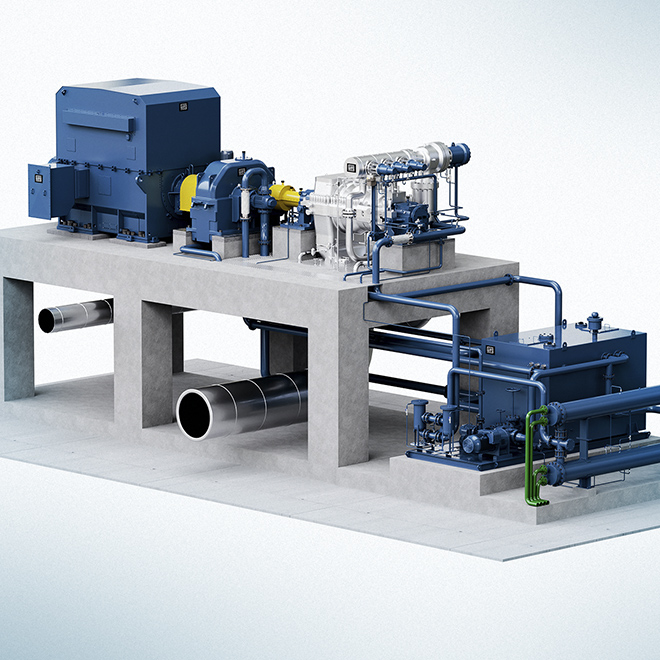

Solução completa e integrada

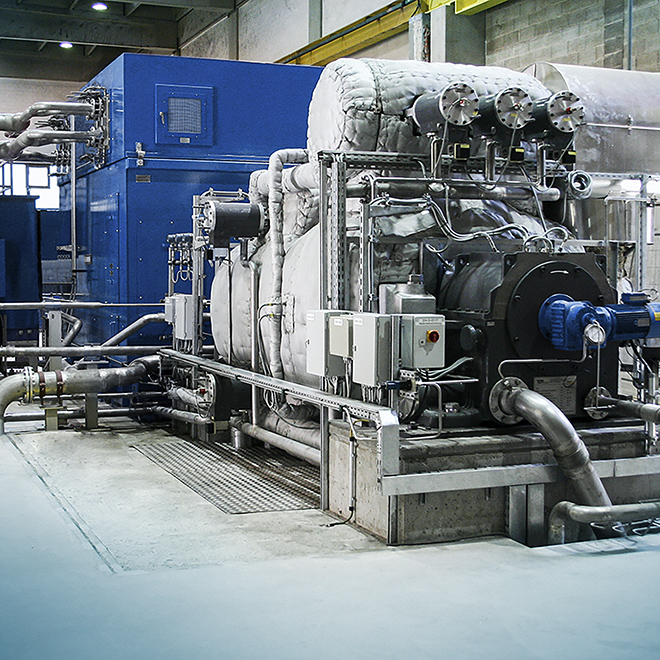

Com as soluções flexíveis, renováveis, integradas e inteligentes de até 200 MVA de potência, a WEG desenvolve e oferece desde a fabricação e a instalação de conjuntos turbogeradores, turbinas a vapor, redutores turbo, geradores, painéis, cubículos, subestações e acessórios até um ágil atendimento pós-vendas.

Nosso fornecimento

- Engenharia/Consultoria

- Estudo de Viabilidade com Balanço Térmico

- Conjunto Turbogerador (Turbina/Redutor/Gerador)

- Sistema Hidráulico

- Sistema de Segurança e Controle

- Painéis/Cubículos

- Subestações

- Acessórios

- Serviços de Campo

- Assistência em pós vendas

Ciclos de aplicação

As soluções WEG são aplicadas em geração de energia a vapor nos ciclos combinados, Rankine e regenerativos em projetos de pequeno a grande porte, operando de acordo com as condições do vapor em baixa, média e alta pressão/temperatura.

Sistema de energia em 2 polos

Sistemas de energia em 4 Polos

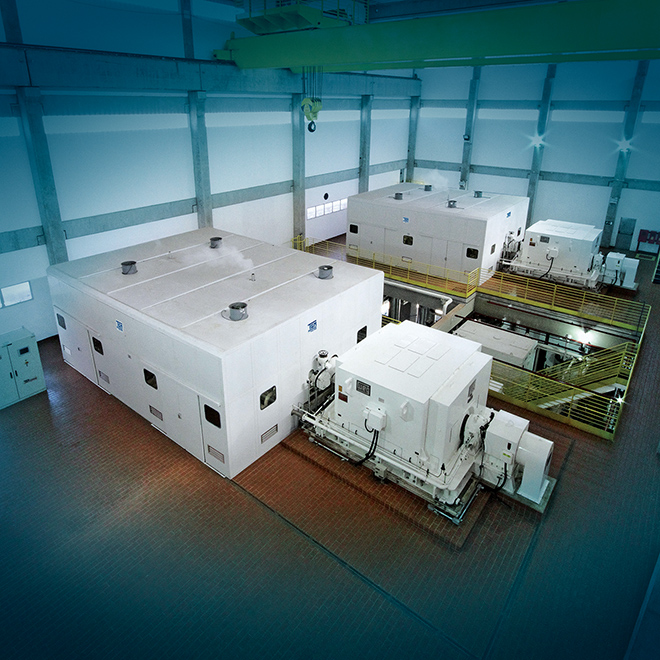

Algumas formas de instalação

- Instalação em Base Metálica

- Instalação em Base Civil

- Configurações de escapes conforme os projetos e disponíveis em radial, full axial e sub axial

Transforme o seu resíduo em energia elétrica com as soluções WEG

A WEG desenvolve e aplica projetos de geração de energia elétrica de qualquer porte, sob medida e com mesma qualidade e tecnologia, desde os primeiros estudos e a fabricação até o atendimento e a implantação.

- Consultoria e Estudos de Viabilidade Técnica

- Engenharia de Estudos de Balanço Térmico

- Engenharia de Sistemas

- Engenharia de Segurança e Controle em Turbomáquinas

- Produtos com elevados níveis de eficiência operacional; seguros, compactos de fácil utilização e baixa manutenção

- Realização de serviços de instalação, monitoramento em pós-vendas

- Estrutura e atendimento em regime de plantão 24h

- Organização e gestão baseadas em diretrizes e metas para a sustentabilidade

- Empresa mundialmente reconhecida por fornecer soluções completas e confiáveis voltadas para eficiência energética e sustentabilidade

Serviços

Todas as soluções e equipamentos são entregues com serviços especializados de campo: instalação, comissionamento, start-up, operação, monitoramento e assistência técnica em pós-venda – um diferencial exclusivo que aumenta a confiabilidade do mercado na WEG.

Reconhecida como autoridade em geração de energia limpa, a WEG também disponibiliza serviços mecânicos, elétricos e eletrônicos aplicados em equipamentos da marca própria e de outros fabricantes, como: revisão, reparos, recuperação, reforma, repotenciação, modernização e manutenção em atendimento de plantão 24h.

Além de turbinas a vapor, redutores, geradores e multiplicadores, são fornecidas soluções completas que abrangem equipamentos mecânicos, elétricos, eletrônicos e digital para indústria 4.0.